Operation Cost reduction by seamless system linkage between ERP and global carriers

Operation Cost reduction by seamless system linkage between ERP and global carriers

![CASE: [America] Stanley Electric Sales of America, Inc.](/en/image/case/stanley/mainimg.jpg)

Warehouse Management System

Stanley Electric Sales of America, Inc. (hereinafter referred to as Stanley), which sells and procures semiconductors, ultra-small light bulbs, electronic equipment products, etc., planned to outsource its own logistics operations and renew its WMS for the new logistics system upon relocating its office in North America. Stanley implemented the distribution center management system "ONEsLOGI/WMS" (hereinafter referred to as ONEsLOGI) of Sunrise Logistics Solutions (America), Ltd., which is the subsidiary of Hitachi Distribution Software Ltd., The features and implementation benefits are as follows.

*Interviewed in October 2019

*Sunrise Logistics Solutions (America), Ltd. changed its name to LOGISTEED Solutions America, Ltd. in April 2023.

*Hitachi Distribution Software Co., Ltd. changed its name to LOGISTEED Solutions, Ltd. in April 2023.

| Index | |

|---|---|

|

|

1.WMS features

Please let us know about the features of the WMS (ONEsLOGI) and the usage status.

ONEsLOGI is a complete package that covers a series of WMS functions required in a warehouse operation, from receiving to shipping.

While making the best use of the basic functions of ONEsLOGI, we added some customizations for the data linkage between systems that was more convenient for business in the American market, which led to reduced labor needs.

- 1

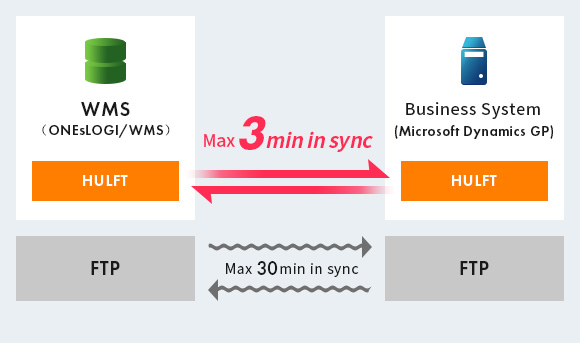

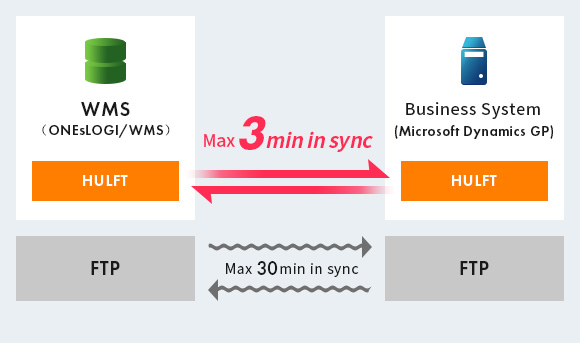

- Established timely data linkage(*1) with Microsoft Dynamics GP by File Linkage Middleware "HULFT" of Saison Information Systems Co., Ltd., for which Sunrise Logistics Solutions (America), Ltd. is a distributor in the American market. File transfer takes up to 30 minutes with FTP (*2), but with "HULFT", now takes only 3 minutes at the most.

- *1 Transaction data linkage(arrival schedule, shipping instruction, arrival record, shipment record, invoice)

Master data linkage(item, shipping destination) - *2 File Transfer Protocol

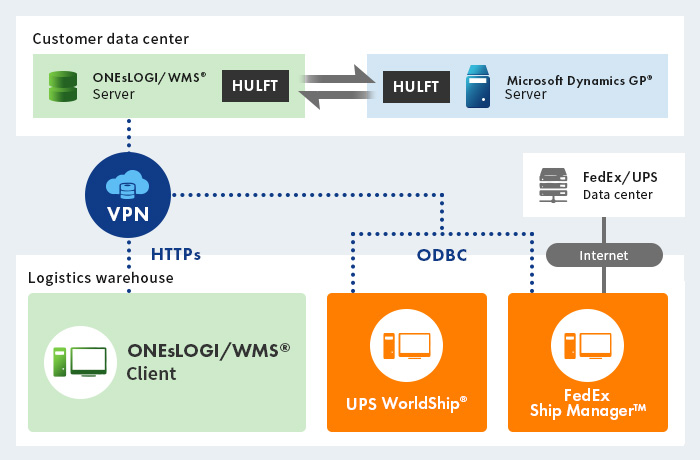

Image of file transfer between ONEsLOGI/WMS and the business system

Notifies the warehousing schedule to WMS from the business system, and reflects the warehousing information from WMS to the business system. Send customer information and shipping instructions to the warehouse based on the latest database on the business system.

Click to enlarge image (new window)

Notifies the warehousing schedule to WMS from the business system, and reflects the warehousing information from WMS to the business system. Send customer information and shipping instructions to the warehouse based on the latest database on the business system.

- 2

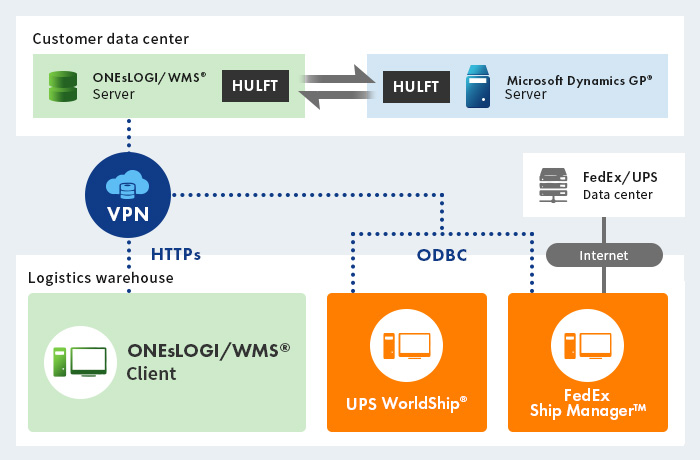

- Implemented database linkage via ODBC with the delivery systems of global carriers such as “FedEx Ship Manager” and “UPS World Ship”.

Image of database linkage between ONEsLOGI/WMS and delivery system

Click to enlarge image (new window)

Image of database linkage between ONEsLOGI/WMS and delivery system

- 3

- Supported lot trace which is required for more accurate management in the American market.

Established management function for each server item for improved management accuracy based on local laws and regulations, reduced workload.

- 4

- Implemented issuing function of shipping documents based on individual shipping destination requirements.

WMS automatically issues shipping documents required based on different shipping conditions for each customer. (40 types; interior labels, exterior labels, packing lists, lot reports, etc.)

- 5

- Implemented issuing function of export document.

Issue commercial invoices and certificates of origin in synchronization with WMS operations.

2.Benefits

Please let us know about the effects after the implementation of ONEsLOGI.

The effects are as follows.

- 1

- Reduction of system operation costs

Data linkage between systems eliminated the need to duplicate input other in-house core systems, delivery company systems, etc., reducing operation costs.

- 2

- Reduction of operation costs

With functions such as Automatic Necessity Judgment, Automatic Issuance, and Management Target Judgment performed by the system, operation costs were reduced for tasks such as time-consuming shipping and export document issuance, lot management.

- 3

- Timely information visualization

By introducing WMS and information linkage, lag time was minimized, allowing for up-to-date visualization of warehouse status, delivery status, and other metrics.

- 4

- Prevention of human error

Overall operations which had been previously handled manually, was standardized and automated, which improved work quality and minimized mistakes made due to human error.

Stanley Electric Sales of America, Inc.

- Head Office

- 36 Executive Park, STE 230, Irvine, CA 92614 U.S.A.

- Businesses

- Sales of semiconductors, ultra-small light bulbs, electronics, etc.